Injecting insulation into window frames doesn’t always reach all the nooks and crannies inside. Those gaps in protection from the summer sizzle and winter chill can translate into higher energy bills. Internorm has developed “EPS” pearls to fill them.

Injecting insulation into window frames doesn’t always reach all the nooks and crannies inside. Those gaps in protection from the summer sizzle and winter chill can translate into higher energy bills. Internorm has developed “EPS” pearls to fill them.

“You might call them Achilles corners,” says Engelbert König, head of product engineering of Internorm. “No matter how good your insulation is, those stubborn little gaps can make the whole window less weather-resistant, less energy-efficient.”

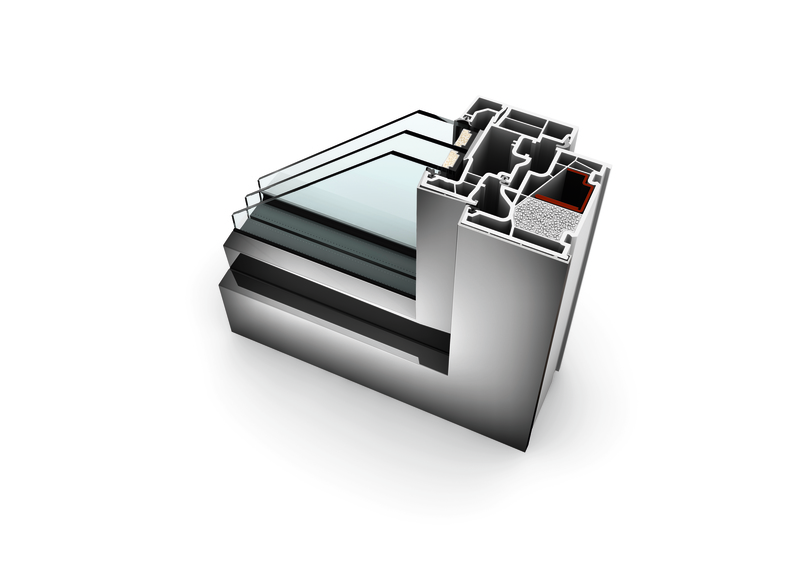

Internorm calls the pearls “Expanded Polystyrene” beads, or EPS. Injected under pressure in to the window frame, they fill in the corners that can let in the heat or cold you’re trying to keep out. The new I-tec insulation is inserted into the inside of the frame of the UPVC/aluminium windows KF 410 and KV 440.

“But to do that, we had to specially design a filling station in the manufacturing process,” König says. “That was some tricky engineering.”

Once past the R&D, Internorm found that the beads improve a window’s insulation by 20%. It’s certified by the Passivhaus Institut in Darmstadt, Germany, an independent institute for high energy efficiency in buildings.

“That means you can save on heating costs, and we use fewer materials for insulation,” König says. They’re also HCFC, HFC and FC-free. “That’s more sustainable all around.”