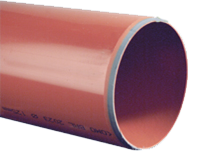

How to increase the recycled content of a three-layer PVC drainage pipe? Working with Alucha, Plastchem, Polymer Science Park, Dyka has developed a way to add regenerated calcium carbonate from paper sludge instead of mining and milling fine-ground calcium carbonate.

How to increase the recycled content of a three-layer PVC drainage pipe? Working with Alucha, Plastchem, Polymer Science Park, Dyka has developed a way to add regenerated calcium carbonate from paper sludge instead of mining and milling fine-ground calcium carbonate.

“This project is a good example of collaborating in the production chain to accelerate circular innovation,” says Rudi Berning, Compounding Manager and Material Specialist at Dyka. “We couldn’t do it without this extended team.”

Here’s how it works. Not all paper waste can be recycled, and to keep it out of the incinerator, Alucha is able to regenerate minerals (circular calcium carbonate) from the paper sludge. Dyka uses that CCC to make PVC pipe.

“We are evaluating the feasibility of replacing mined calcium carbonate or GCC, with that circular calcium carbonate (CCC) from paper sludge waste in a three-layer PVC pipe,” Rudi says. The inner layer of the pipe can be made out of 100% circular content. This results in an increase of circular content in the final product from 40% to 50%: Dyka’s circularity target for 2030.

The project, Circular Calcium Carbonate or CCC4PVC, supported by Overijssel Province, is finalised but more tests are planned on a larger scale, so stay tuned. More on Dyka’s sustainability in this video.